Vincent Van Gogh once said, “Great things are done by a series of small things brought together.” This wisdom applies to sustainability too—especially when it comes to reducing plastic packaging. While energy and water use grab the focus of many sustainability programs, packaging waste is a highly visible and easily solvable area where companies make a meaningful difference. Single-use plastic packaging continues to be the leading source of packaging waste.

Plastic packaging waste doesn’t only impact the environment. It can affect human health, drive up waste management costs and even erode customer trust. Fortunately, you don’t have to be a sustainability expert to start making changes. Some of the most practical and impactful improvements come from areas in your operation that are easy to overlook—like swapping out packaging used for spare parts, processes and samples.

If you’re looking to reduce plastic use throughout your business, here are six simple actions you can take to show your customers and team that you’re serious about making strides in your sustainability efforts:

- Experiment with Sample Packaging

If you give product samples out at tradeshows, events or upon customer request, look at the packaging used to distribute these samples. This is a great way to dip your toe in the water and try new paper-based materials, test performance and gain feedback from your customers, all without disrupting production.

Try this: Replace plastic sachets with recyclable paper pouches or test how your product works with fiber-based packaging. Bonus: JBM can help fill and assemble your product samples to meet quick deadlines.Example: ECOS needed a lightweight packaging solution for its sustainable dryer sheet samples to distribute to tradeshow attendees. JBM developed an open-ended pouch with a water-based latex closure that perfectly fit the sample product.

Why it works: It’s a simple switch with a big branding bonus. Paper-based sample packaging can come in any shape or size, reinforce your values and wow potential customers

- Rethink Internal Packaging

Packaging doesn’t always start with shipping. A lot of operations use plastic bags to store or move components between departments.

Try this: Replace single-use plastic options with recyclable paper alternatives like glassine bags with resealable adhesive options or paper pouches like our Spear Envelopes with a fold-n-tuck function, which is perfect for reuse.Example: A leading consumer electronics manufacturer identified an opportunity to eliminate plastic bags used to hold parts before assembly as part of a corporate sustainability program. It replaced them with open-ended envelopes that could be recycled after use.

Why it works: We often default to plastic packaging for internal processes because it’s cheap and easy. Transitioning to a paper-based alternative gives you something to tout on social media and in sustainability reports. The best part? It shows transparency and doesn’t require external distribution channel approval.

- Upgrade Your Return Process

If you offer exchanges, recycling or takeback programs, look at what your customers use to return items. Sustainable return packaging can improve the customer experience and increase overall participation in takeback programs. This small, but impactful opportunity also allows you to move the needle on sustainability without impacting your product manufacturing process.

Try this: Swap unsightly plastic polybags for heavyweight, water-resistant paper packaging with an adhesive closure to keep contents safe in transport.

Example: A popular phone manufacturer moved from plastic to open-ended paper envelopes for device returns. Customers liked the recyclability and biodegradability of the new return packaging.Why it Works: Reducing the amount of packaging materials used in the return process can be just as impactful as improving the materials’ sustainability. Ultimately, the packaging material you chose should be durable and communicate return instructions for easy use—remember, it’s an extension of your brand experience.

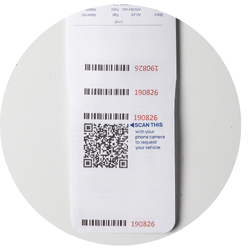

- Lose the Label

Plastic-backed labels and adhesives may seem small, but they can add layers of waste and complexity to recycling programs. By printing directly on the packaging, it eliminates that step entirely.

Try this:

Use QR codes, shipping info and barcodes printed straight onto your paper packages or pouches to eliminate the need for adhesives.Example: A hospitality partner used our unique sequentially barcode printing capability to improve customer experience for their valet parking process. At drop-off, the customer scans the barcode to register their vehicle and secures their keys inside the envelope for valet attendants.

Why it Works: With printing capabilities continuing to evolve, brands can put almost anything onto their packaging to avoid the use of labels and added materials that cause issues in the recycling stream. Think engagement activations, custom audience promotions and so much more!

- Find an Alternative for Plastic Drinking Cups

Plastic water cooler cups and single-use medicine cups may seem like minor items, but they add up quickly, particularly in busy manufacturing environments with several shift changes. These types of high-turnover disposables create a steady stream of plastic waste that can be easily overlooked.

Why it works:

It’s another one of those behind-the-scenes improvements that can quickly add up. A simple cup swap immediately tells employees that you’re making sustainability a priority.Example: A healthcare provider looking to obtain Practice Greenhealth certification eliminated more than 100,000 plastic cups annually by switching to paper-based medication cups and reusable breakroom drinkware.

- Elevate Spare, Replacement Part and Hardware Packaging

Spare parts usually get utilitarian packaging—often in plastic. Swapping them with a paper alternative allows you to avoid single-use packaging that is often never even used.

Example:

REI transitioned its replacement hardware kits from plastic sleeves to branded paper bags. The switch held up in transit and aligned with their commitment to reducing plastic use.Tip: Print installation instructions or QR codes directly on the bag to save paper and eliminate extra .

Start Small, Think Big

You don’t have to overhaul your entire packaging strategy to make an impact. These small shifts are doable, practical and designed to be starters that enable you to build momentum toward broader sustainability efforts.

But despite their environmental benefits, paper-based alternatives and more durable recyclable materials may have higher upfront costs. That’s why starting small and piloting changes is essential: it gives time to test and evaluate performance, gather feedback and determine whether or not the long-term savings balances out the investment.

Need help figuring out where to start? We can help you identify smart swaps and easy wins that make sense for your business.